Lewatit®

Ion Exchange Resins

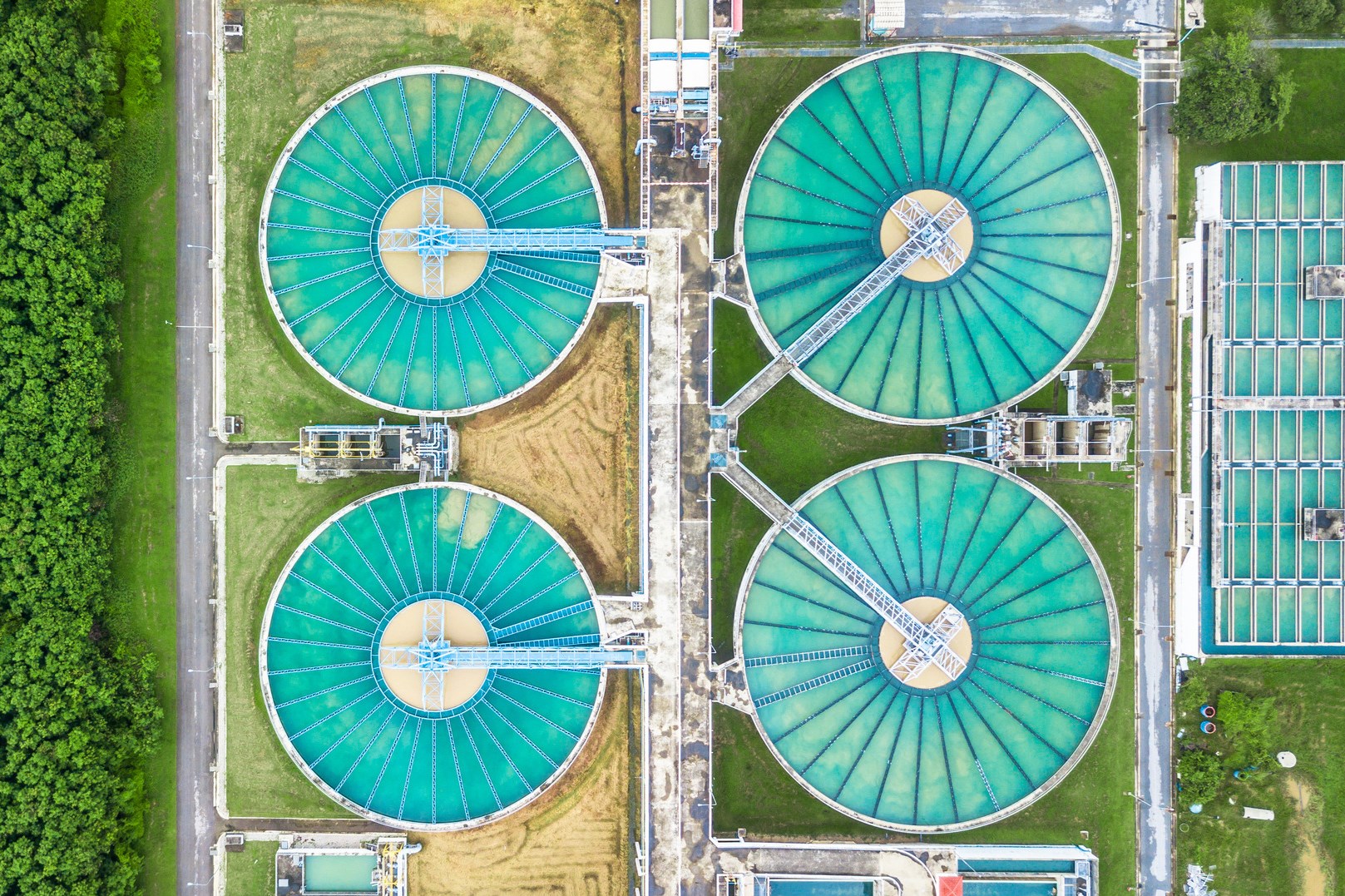

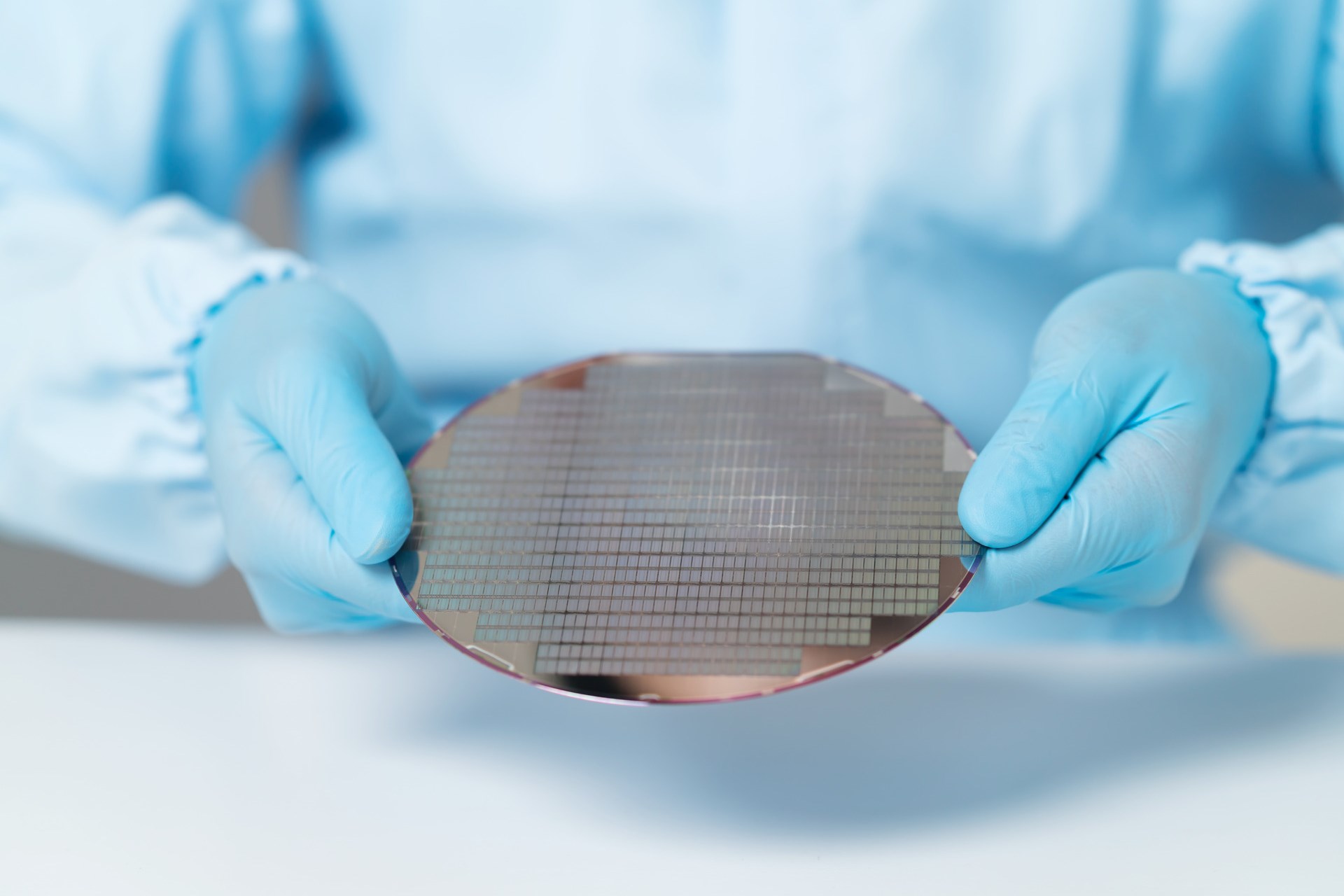

LANXESS is a leading global ion exchange resin manufacturer and solution provider for water treatment and liquid purification with excellent technical Know-how and customer service. For more than 80 years our Lewatit® ion exchange resins and adsorbers are used in numerous industries to treat and purify water and other liquid media. In addition, we offer a range of Bayoxide® iron oxide adsorbers for various water treatment applications.

BY THE NUMBERS – LIQUID PURIFICATION TECHNOLOGIES BUSINESS UNIT

>

0

Years of Market Experience

>

0

Products

0

Employees

0

Production Units